Xore customer case Boliden, Rönnskär

A plant with two Boxray Compact analyzers. In Sweden, outside the town of Skelleftea by the Gulf of Bothnia, lies Boliden Ronnskar smelter. It is one of the world’s most efficient copper smelters and the world’s leading recycler of electronic scrap.

Two Boxray Compact analyzers are utilized in the plant; one in the electrolytic refinery, monitoring copper content in the electrolyte. Another Boxray Compact analyzer is used to monitor metal content in the process water in the process water treatment plant. Both have been in operation for more than 15 years.

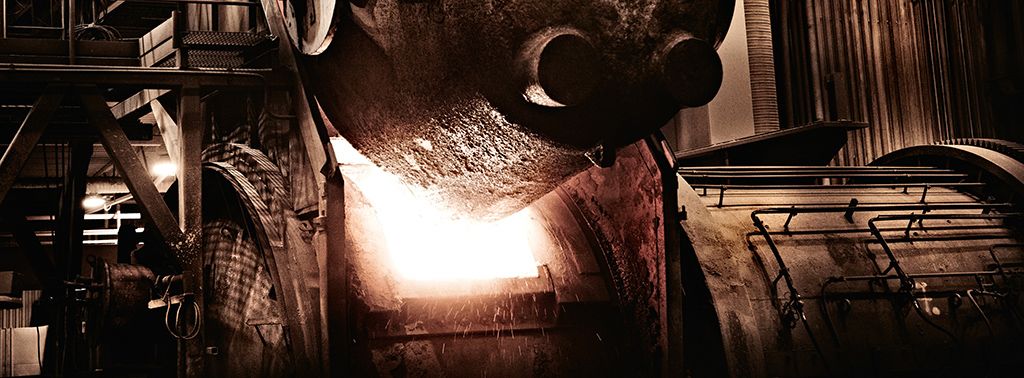

Electrolytic Refinery

Prior to the Boxray Compact analyzers was installed in the refinery, sampling was done manually and samples were analyzed in the lab on site. This is still normal procedure in many plants of this type. There are many drawbacks with manual sampling, for obvious reasons is difficult to handle aggressive samples at high temperatures, and if the sample cools down it is destroyed. Manual analysis is also too slow to use for meaningful process control, typically there are only a few samples analyzed each day and the results become available long after they were taken.

The electrolytic refinery then invested in a Boxray Compact online analyzer to monitor copper content in the sulphuric acid. The data from the analyzer is not just used for information; it is used as vital information for process control. The copper concentration in the acid must be kept within a certain window in order to keep the process at peak performance. An online analyzer is the only source of process data that can handle the aggressive solution and give reliable data at a high pace.

With more than a decade in operation both the analyzer and application are well proven for reliability and profitability. It also offers improvement in workplace safety as the manual handling of samples is eliminated and it frees up resources in the lab that is better used to interpret the data from the analyzer and maintaining the process at it’s peak.

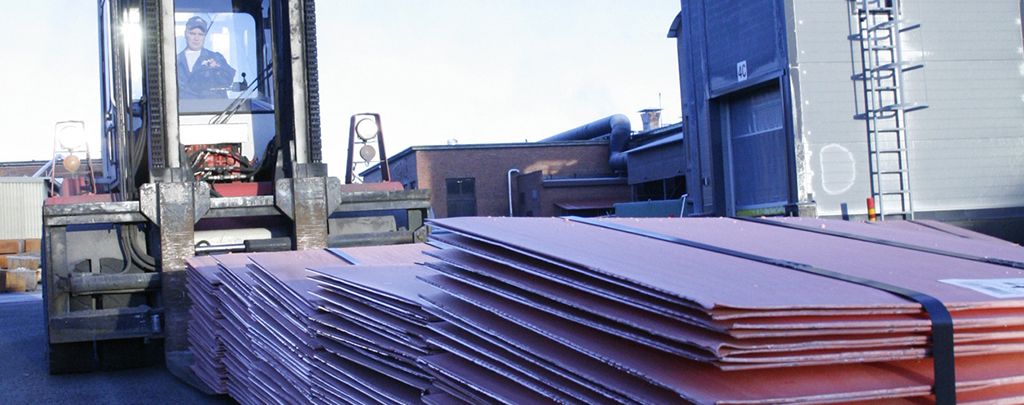

Water Treatment

Water supply and responsible discharge of process water from industries is a topic becoming more and more relevant. Boliden Ronnskar smelter used manual sampling in its water treatment process until 2001 when they invested in a Boxray Compact online analyzer. The water treatment process used to be adjusted based on the manual samples and analysis by the laboratory on site. As manual sampling and analysis is time consuming it sets a limit for how often the process can be adjusted.

Increased speed with Boxray Compact analyzers

The Boxray Compact analyzer first and foremost offers increased measurement speed. Instead of having a few hours between the samples the interval is now down to a few minutes. Regardless if the water treatment process control is manual or automated the reduced sampling interval is a foundation for a better functioning process.

The very low grades of metals in the process water set very high requirements on the analyzer. The Boxray analyzer’s energy dispersive detector is very sensitive and up to the task. Although the metal contents are low the typical measurement time is one minute or less.

The data from the analyzer is stored and can be used as a logbook proving that the industry is handling its waste responsibly and not releasing water with poor quality back to nature.

The environment also benefits from a better water treatment process; it reduces use of chemicals and the water released back to the river or sea has better quality.

The return of investment for an analyzer in a water treatment plant comes from e.g. savings on chemicals used in the process. Manual sampling often leads to overdosing on chemicals, as it cannot follow process variations tightly.

Very beneficial

Recycling process water is beneficial from many aspects; it reduces the demand on water supply from sources around a plant and it reduces emissions. Pumping water from a pond or well is expensive and e.g. dams are complicated structures that are heavily regulated. Reducing water from these sources also reduces a lot of trouble that comes with them.

The foundation for recycling water is that it can be properly cleaned in order to be used again and in order to do this with maximum efficiency an on-stream Boxray Compact analyzer from Xore has to be used.

| Boliden Ronnskar | Production |

| Copper cathodes | 200 ktonnes |

| Gold | 12 tonnes |

| Silver | 500 tonnes |

| Lead | 25 ktonnes |

| Palladium conc | 2 tonnes |